29

2024

-

01

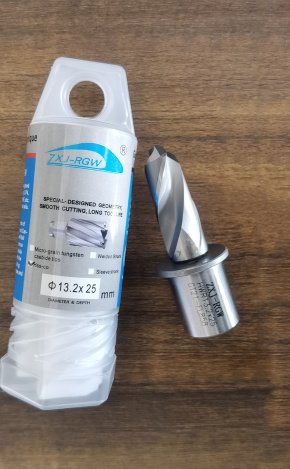

Hollow drill bit: a sharp tool for efficient drilling

In the field of drilling, hollow drill is an important tool, its performance directly affects the efficiency

In the field of drilling, hollow drill is an important tool, its performance directly affects the efficiency and quality of drilling. This article will introduce the characteristics, application scenarios and advantages of hollow drill bits in detail.

Features of 1. hollow drill bits

High efficiency: The hollow drill bit adopts a unique structural design, which can realize rapid drilling and improve production efficiency.

Long life: The hollow drill bit adopts high quality materials and advanced production technology, which has high wear resistance and durability, and prolongs the service life.

Good heat dissipation: The hollow drill bit has good heat dissipation performance and can quickly discharge the heat generated during the drilling process to ensure the stability of the drilling process.

Wide applicability: Hollow drill bits are suitable for drilling of various materials and apertures, such as metal, plastic, wood, etc.

Application Scenario of 2. Hollow Drill

Metal processing: In the field of metal processing, hollow drill bits are used for drilling, such as machinery manufacturing, mold manufacturing, etc.

Building decoration: In building decoration, hollow drill bits are used for drilling and installation, such as wall drilling, floor drilling, etc.

Woodworking: In the field of woodworking processing, hollow drill bits are used for drilling, such as furniture production, wood carving, etc.

Electronic manufacturing: In electronic manufacturing, hollow drill bits are used for drilling and installation, such as circuit board drilling, electronic component installation, etc.

Advantages of 3. hollow drill bits

Improve production efficiency: The efficiency design of the hollow drill bit can quickly complete the drilling task, shorten the production cycle, and improve production efficiency.

Extend the service life: The long-life design of the hollow drill bit reduces the frequency of replacing the drill bit and reduces the production cost.

Improve drilling quality: The good heat dissipation performance of the hollow drill bit ensures the stability of the drilling process and improves the drilling quality.

Strong applicability: The hollow drill bit is suitable for drilling of various materials and diameters, and meets the drilling needs of different fields.

Examples of 4. use

Taking a machinery manufacturing enterprise as an example, the enterprise needs a lot of drilling in the production process. In order to improve production efficiency and drilling quality, enterprises have chosen hollow drill bits as drilling tools. By using hollow drill bits, the company successfully improved the drilling speed, reduced the production cost, ensured the drilling quality, and improved the market competitiveness of the company.

In short, the hollow drill bit has become an important tool in the field of drilling processing because of its high efficiency, long life, good heat dissipation and strong applicability. In the future, the hollow drill will continue to play its advantages in the field of drilling, to provide customers with better products and services, and promote the development of drilling technology.

Hollow drill bit

Previous Page