04

2024

-

02

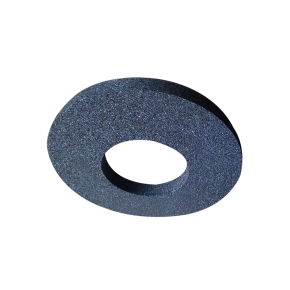

Hollow drill bit-a sharp tool for efficient drilling

In the fields of construction, mining and geological exploration, drilling is an indispensable link.

In the fields of construction, mining and geological exploration, drilling is an indispensable link. As an efficient drilling tool, hollow drill bit has become the first choice of drilling operation with its unique design and excellent performance. This paper will introduce the structural characteristics, working principle and advantages of hollow drill bits in practical application.

Structural characteristics of 1. hollow drill bits

The main body of the hollow drill bit is of hollow design, and a cooling liquid channel is arranged inside. The front end of the drill is a cutting edge for cutting rock or other hard materials. The structural features of the hollow drill are as follows:

Hollow design: The center of the hollow drill bit is hollow, which can reduce the weight of the drill bit and reduce the energy consumption in the drilling process.

Coolant channel: Coolant channel is arranged inside the hollow drill bit to cool the drill bit and bring the cut rock powder out of the drill hole.

Cutting edge: The front end of the hollow drill bit is equipped with a cutting edge made of cemented carbide or other wear-resistant materials, which is used to efficiently cut rocks or other hard materials.

The working principle of 2. hollow drill bit

Hollow drill bit In drilling operations, drilling is carried out by means of rotation and propulsion. Its working principle is as follows:

Rotation: The hollow drill bit rotates under the action of the drill, and the cutting edge contacts the rock to start the cutting process.

Propulsion: At the same time, the drilling rig applies propulsion force to the hollow drill bit, so that the drill bit continues to penetrate into the rock.

Coolant circulation: The coolant flows in from the inlet of the hollow drill bit, passes through the internal channel, cools the drill bit and the cutting edge, and takes the cut rock powder out of the drill hole.

Rock powder discharge: the coolant carries rock powder through the outlet of the hollow drill bit to form a borehole.

Advantages of 3. hollow drill bits

High efficiency: The hollow drill bit is designed to cut the rock faster during the drilling process, improving drilling efficiency.

Strong wear resistance: The hollow drill bit is made of hard alloy or other wear-resistant materials, which has strong wear resistance and can be used for a long time.

Good cooling performance: The coolant channel design of the hollow drill bit can effectively cool the drill bit and the cutting edge and improve the service life of the drill bit.

Lightweight: The hollow design of the hollow drill bit reduces the weight of the drill bit and reduces the energy consumption and labor intensity in the drilling process.

Use example of 4. hollow drill bit

The following is an example of a scenario in which a hollow drill bit is used in infrastructure construction to illustrate its advantages in practical applications.

Project Requirements: The construction of infrastructure requires the drilling of a large number of deep holes in the rock geology to meet the needs of concrete injection and foundation pile construction.

Choosing a hollow drill bit: In order to improve the drilling efficiency and quality, the construction party decided to use a hollow drill bit for drilling operations.

Application of hollow drill bit: The construction party installs the hollow drill bit on the drilling rig to drill by rotating and advancing.

Efficient drilling: the use of hollow drill bit makes the drilling operation more efficient, greatly shortens the construction period and reduces the cost.

5. epilogue

Hollow bit with its unique structural design and high efficiency, high wear resistance and other advantages, has become a tool for drilling operations. With the continuous development of construction, mining, geological exploration and other industries, the application of hollow drill bits will be more extensive, providing efficient solutions for drilling operations.

Hollow drill bit