19

2023

-

12

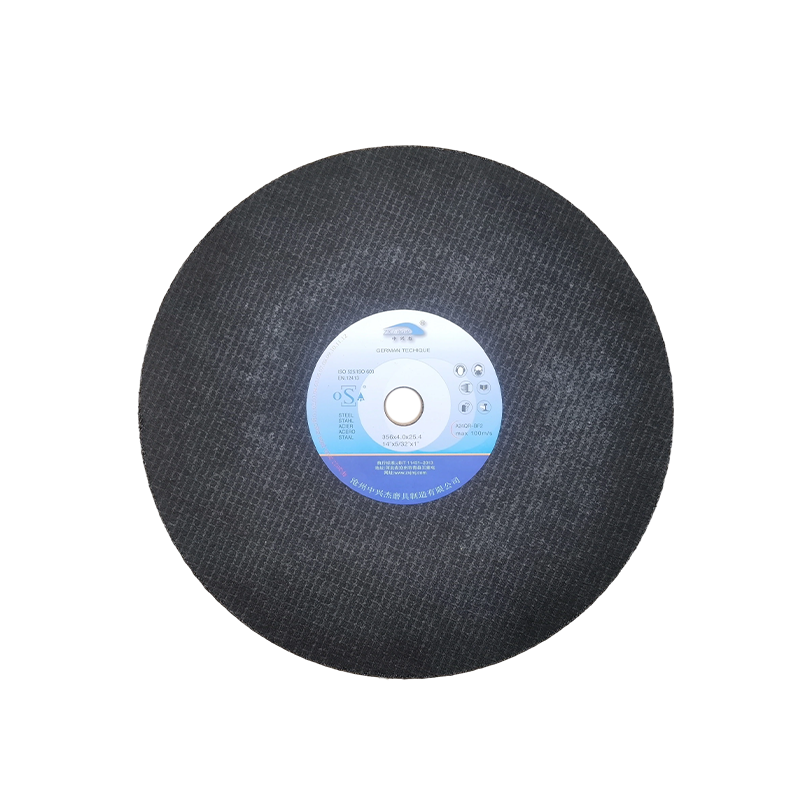

High-speed cutting: a sharp tool in the field of industrial cutting

1. Introduction As an effective cutting tool, high-speed cutting pieces are widely

1. Introduction

As an effective cutting tool, high-speed cutting pieces are widely used in industrial cutting fields, such as metal processing and stone processing. It has the advantages of fast cutting speed, high precision and strong durability, which provides strong support for industrial production. This article will give you a detailed description of the characteristics, applications and advantages of high-speed cutting.

Features of 2. high-speed cutting pieces

Fast cutting speed: The high-speed cutting blade adopts advanced materials and technology to realize high-speed cutting and improve production efficiency.

High precision: high-speed cutting blade with high precision cutting performance, to meet the accuracy requirements of all kinds of industrial cutting.

Strong durability: The high-speed cutting piece adopts excellent materials, which has good wear resistance and impact resistance, and prolongs the service life.

Wide range of applications: High-speed cutting blades can be applied to various metal materials, especially for high-strength, high-hardness and other refractory materials with good cutting performance.

Application fields of 3. high-speed cutting pieces

Metal processing: used to cut all kinds of metal materials, such as stainless steel, aluminum, copper, etc.

Stone processing: used for cutting marble, granite and other stone materials.

Machinery manufacturing: used for cutting mechanical parts, molds, etc.

Construction industry: used for cutting construction steel, concrete, etc.

Advantages of 4. high-speed cutting pieces

Improve production efficiency: high-speed cutting blades realize high-speed cutting, reduce cutting time and improve production efficiency.

Reduce production costs: high-speed cutting blades have strong durability, low replacement frequency, and reduce production costs.

Excellent cutting effect: high-speed cutting disc has high cutting accuracy, smooth cutting surface, and reduces subsequent processing procedures.

Safety and environmental protection: The high-speed cutting piece adopts a closed design to effectively prevent sparks and dust generated during the cutting process from harming the environment and the human body.

Selection and Maintenance of 5. High Speed Cutting Pieces

Selection: Select the appropriate high-speed cutting piece according to the cutting material, cutting thickness and other factors.

Maintenance: Regularly check the wear of the high-speed cutting piece, and replace the severely worn cutting piece in time to ensure the cutting effect.

6. Summary

As an effective cutting tool, high-speed cutting blades are widely used in industrial cutting fields. It has the advantages of fast cutting speed, high precision and strong durability, which provides strong support for industrial production. Choosing the right high-speed cutting piece and carrying out reasonable maintenance will bring higher benefits to your career. In the future industrial production, let us join hands in high-speed cutting pieces to create a better future.

High speed cutting sheet